BLACKMER LPG LB Compressor Series RECIPROCATING GAS COMPRESSORS

Oil-Free Gas BLACKMER Compressors for Liquid Transfer and Vapor Recovery (Kopie)

Blackmer oil-free gas compressors deliver high efficiency in handling LPG (propane and butane) and anhydrous ammonia. The LB Series of BLACKMER Reciprocating Gas Compressors are ideal for railcar, storage, and truck vessel unloading in addition to associated vapor recovery applications. The single-stage reciprocating gas compressors are designed to give maximum performance and reliability under the most severe service conditions. All BLACKMER LB Compressors are equipped with a ductile iron head and cylinder providing greater resistance to both thermal and mechanical shock. Additionally, the entire interior of the crankcase is coated, with a specially formulated epoxy coating, providing an added layer of protection for the compressor Equipped with high-efficiency valves, heavy-duty pistons, self adjusting piston rod seals and other robust features, the BLACKMER LB Series Compressors are designed for quiet efficient operation and ease of maintenance, with all components readily accessible for simple, quick, and easy replacement. Models are available with liquid transfer delivery rates up 2,575 L/min and piston displacement capacities from 11.9 to 212 m³/h with working pressure up to 24.13 bar.

SUPERIOR MATERIALS OF CONSTRUCTION With a special epoxy coating that protects the entire interior of the crankcase, and with numerous durable and robust components like high-efficiency valves, heavy-duty pistons, self-adjusting piston rod seals, wear-resistant crosshead assemblies, among others, the BLACKMER LB Series Gas Compressors are built to last in the harshest conditions. SUPERIOR DESIGN Designed so that components are readily accessible, BLACKMER LB Compressors make routine maintenance and replacement of wear parts simple, quick and easy.

BLACKMER LB Compressor Series | Standard Features (Kopie)

Special Epoxy Coating

The entire interior of the crankcase is coated with a specially formulated epoxy coating, providing an added layer of protection.

BLACKMER Ductile Iron Cylinder and Head

Ductile iron is stronger, much more resistant to thermal shock, and more corrosion resistant than ordinary cast iron.

BLACKMER O-Ring Seals Between the Cylinder and Head

O-rings in place of flat gaskets eliminate leakage and maintenance problems.

BLACKMER High Efficiency Valves

Designed to move more gas volume, Blackmer high efficiency steel valves are built for toughness and simplicity.

Constructed of corrosion resistant stainless steel discs and springs, the valves are easily removed for service without disturbing the piping. With their simple design they are easily repaired and reassembled.

BLACKMER One Piece Piston with Single Positive Locking Nut

The one-piece heavy-duty piston and single positive locking nut are both stronger and simpler than multi-piece designs with numerous fasteners found on competitor’s equipment. The LB940 Series features a two-piece piston design.

BLACKMER Pressure Assisted PTFE Piston Rings for Positive Sealing

A special chamber ensures pressure behind the ring to provide maximum sealing efficiency with minimal friction wear.

No Packing Adjustment Nut

The Blackmer spring loaded packing never requires adjustment. No expensive scored rods due to over tightened packing.

Wear Resistant Crosshead Assemblies

Pressure Lubricated Crankcase

Oversized Main Bearings

The ductile iron crossheads feature special machined lubrication channels and ports to provide extensive lubrication of the crosshead and guide. Wear is minimized and galling is eliminated.

An oil pump directly driven by the crankshaft ensures positive lubrication of all bearing surfaces. The oil pump is

self-reversing for either direction of rotation and is available with an external automotive type oil filter for extra protection.

LB Compressors | Compressor Selections

To select a compressor that best fits your application requirements, use the charts shown. The data provided is based on approximate delivery rates when handling LPG or anhydrous ammonia. Actual capacities will depend upon line restrictions, size and length of piping. Horsepower requirements for both liquid transfer and vapor recovery applications are based on moderate climatic conditions.

1* One single-acting cylinder

2* Two single-acting cylinders

3* Two double-acting cylinders

4* Compression Ratio defined as absolute discharge pressure divided by absolute inlet pressure.

5* Compression Ratios are limited by discharge temperature. High compression ratios can create excessive heat, i.e., over 177°C.

The duty cycle must provide for adequate cooling time between periods of operation to prevent excessive operating temperature.

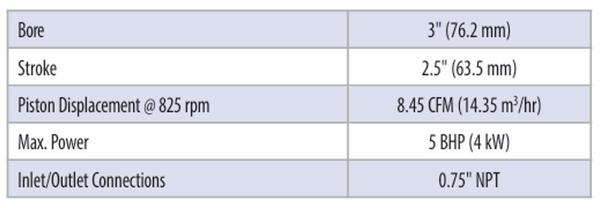

The smallest BLACKMER LB Compressor available. This compact compressor features one cylinder and is well suited for portable use, small vessel unloading, and vapor recovery applications. The BLACKMER LB080 Series has a flow rate of 14.35 m3/hr at 825 rpm.

BLACKMER LB081 - Top End Repair Kit - 791129

BLACKMER LB081 - Intermediate Repair Kit - 791130

Available as bare shaft compressor or as complete EDS-BLACKMER COMPRESSOR SKID

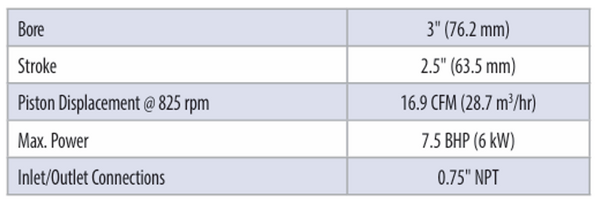

Slightly larger than the BLACKMER LB080 series, the BLACKMER LB160 Series is a two-cylinder compressor that features higher flow rates of 28.7 m3/hr at 825 rpm.

BLACKMER LB161 - Top End Repair Kit - 792229

BLACKMER LB161 - Intermediate Repair Kit - 792230

Available as bare shaft compressor or as complete EDS-BLACKMER COMPRESSOR SKID

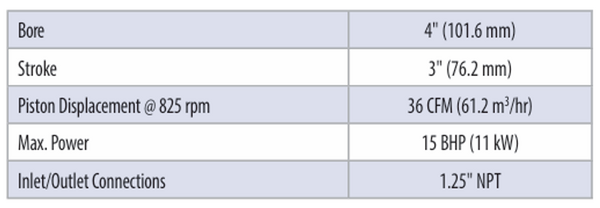

The BLACKMER LB360 Series two-cylinder compressor provides flow rates of 61.2 m3/hr at 825 rpm.

BLACKMER LB361 - Top End Repair Kit - 793229

BLACKMER LB361 - Intermediate Repair Kit - 793230

Available as bare shaft compressor or as complete EDS-BLACKMER COMPRESSOR SKID

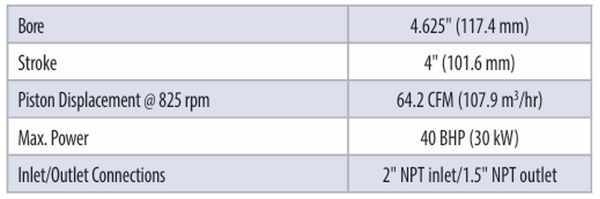

As one of the larger BLACKMER LB models, the BLACKMER LB600 Series is a two-cylinder compressor that offers flow rates of 107.9 m3/hr at 825 rpm. Additionally, BLACKMER LB600 Series Compressors are equipped with special features not available on smaller units:

- The S3R oil control seal, only available in the BLACKMER LB602, keeps oil in the crankcase and prevents oil migration within the compressor

- Special needle bearings designed for full load capability

BLACKMER LB601 - Top End Repair Kit - 794237

BLACKMER LB601 - Intermediate Repair Kit - 794238

Available as bare shaft compressor or as complete EDS-BLACKMER COMPRESSOR SKID

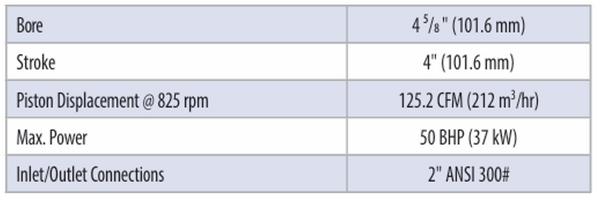

Equipped with two double-acting cylinders, the BLACKMER LB940 Series compressors provide high volume fluid transfer and gas compression for large applications from barges, ships, and railcars. They offer high flow rates of 212 m3/h at 825 rpm. These high-capacity compressors are also equipped with thick and robust wear parts – piston rings, wrist pins, needle bearings and valves that will keep the compressor operating over longer periods between maintenance cycles than the competition. BLACKMER LB940 Series Compressors have numerous other construction, component, and design advantages not found on competitive units. SUPERIOR MATERIALS OF CONSTRUCTION Constructed with materials that won’t degrade when exposed to harsh gases, the BLACKMER LB940 Compressors reliably operate in demanding applications.

- PEEK valve plates with option for all stainless steel

- Stainless steel suction valve unloaders

- No yellow metals

- Steel wrist pin needle bearings SUPERIOR WEARING COMPONENTS Blackmer LB940 Series Compressor wear components are built to last, providing you with peak performance and extended service life.

- Oversize piston rings for longer life

- Wrist pin needle bearing for even loading

- Oversize main bearings SUPERIOR DESIGN Designed for simplicity, Blackmer LB940 Series Compressors make routine maintenance and replacement of wear parts simple, quick, and easy.

- Oversize valves for improved gas flow

- One piece piston with single lock nut

- Full load capability with needle bearings

- S3R oil control seal keeps oil in the crankcase and prevents oil migration within the compressor

Available as bare shaft compressor or as complete EDS-BLACKMER COMPRESSOR SKID