Reciprocating Gas Compressors

Blackmer NG series

BLACKMER NG Compressors - Natural Gas Compressors

Specially designed for the oilfield, the BLACKMER NG Series Reciprocating Gas Compressors have proven themselves over and over as dependable and robust equipment for oil and natural gas production, vapor recovery and storage operations. These oil-free reciprocating gas compressors are constructed and equipped with superior components, which help provide maximum performance and reliability under the most severe service conditions. BLACKMER NG Series Reciprocating Gas Compressors are highly efficient, heavy duty single- and two-stage oil-free compressors. Each BLACKMER NG Series Compressor is constructed with a single distance piece between two sets of seals on each piston rod. The distance piece provides leakage control and prevents oil contamination of the compressed gas stream. Ports are provided in the distance piece chamber for purging, pressurizing or venting. This enables NG Series Compressors to be utilized in a wide range of wellhead applications for oil-and-gas production and storage operations. Additionally, NGS Series Sour Gas compressors can handle liquefied gases with up to 8% dry hydrogen sulfide (H2S) content

Applications

- Wellhead Annulus Gas Pressure Reduction

- Gas Gathering

- Wellhead Vapor Control

- Gas Evacuation

- Pressure Boosting 2

- Gas Blanketing

- Tank Battery Vapor Control and Recovery

- Flare Elimination

- Vapor Recovery

- Enhanced Recovery

Blackmer NG Compressors | Standard Features

All Blackmer NG Compressor models feature an oil-free design and high efficiency valves that provide superior sealing characteristics, high efficiency and durability. This makes them ideal for use in the most severe oilfield and wellhead applications.

Other standard features include:

- A heavy-duty, precision-ground crankshaft for smooth, quiet operation with long-lasting bearings

- A specially formulated crankcase epoxy coating for added protection

- Self-adjusting loaded-glass PTFE piston-rod seals that maintain constant sealing pressure that helps prevent oil contamination and cylinder blow-by

- One-piece ductile-iron pistons connected to the piston rod with a single positive-locking nut for added strength and easier maintenance

- Self-reversing oil pump that lubricates the crankcase and all running gear components through positive oil distribution

- An S3R oil-control seal that keeps oil in the crankcase for enhanced leakage control

- High-efficiency, long-lasting valves with precision-engineered clearances and spring tension that allow the movement of more gas volume with each piston stroke

Specific features of the NG Series Compressors include:

- No use of yellow metals (brass and copper) for protection against corrosion

- Self-lubricating PTFE piston rings with a special pressure-assisted design for maximum efficiency with minimal friction wear

- Steel wrist-pin needle bearings for long life when used in high rod-load applications with wrist-pin lubrication assured under all load conditions

- Isolation chambers with single-distance pieces for leakage control, keeps crankcase lubricant isolated from the compression chamber

- Pressure-containing parts sealed with FKM or PTFE O-rings for positive sealing under all operating conditions

- Valves and valve plates constructed of self-lubricating PEEK material for superior sealing, high efficiency and extended service life; optional stainless-steel valves are also available

Wherever wellhead gases need to be cost-effectively extracted and efficiently managed, Blackmer NG Series Gas Compressors are on the job.

With decades of deep oil and gas industry experience, Blackmer earned its reputation for product innovation, quality, and most critical to Wellhead Operators – reliability – especially in rugged and remote unmanned locations. These professionals rely on Blackmer NG Gas Compressors to perform without fail at the wellhead and storage tank batteries for an array of critical applications.

Annulus Reduction

Blackmer NG Compressors reduce wellhead gas pressure improving oil flow into underground formations for more efficient oil production enhancement.

Vapor Control

The wellhead and tank batteries are the two major sources of fugitive methane emissions. Common air compressors lack critical seals to prevent gas leakage and crankcase oil dilution. Condensate can form in the compressor, which will contaminate crankcase oil. Condensate will break down the oil acting like a solvent, stripping bearings of critical lubrication. The result is damaging heat, friction, and equipment damage or breakdown. Blackmer NG Compressors are specially designed to capture and control wellhead gases. The design prevents gas leakage and oil contamination.

Vapor Recovery

Increasingly stringent state and federal clean air rules are promoting the reduction and elimination of gas venting and flaring of fugitive gas emissions. Blackmer NG Compressors are unsurpassed in reducing emissions and the recovery of saleable wellhead gas, thus protecting the environment, supporting regulatory compliance and improving the bottom line

Product Transfer

Blackmer NG Compressors move wellhead and tank battery vapors into low to medium pressure pipelines where it can be further processed downstream at a gas processing station. Wellhead operators attest to the importance of equipment reliability and uptime performance, and understand the risks and downtime costs of relying upon less capable, less durable air compressors. They avoid the unnecessary expense of daily and weekly oil changes, and the frequent replacement of these less durable compressors. They recognize the Blackmer product outlasts and outperforms, requiring only routine maintenance. Its ability to remain on 24/7/365 continuous duty for the long haul is testimony to Blackmer reliability and bottom line results.

Blackmer NG Compressors | Specifications

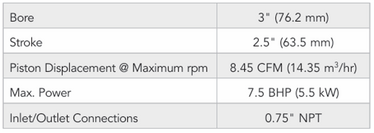

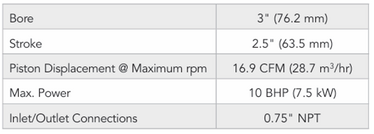

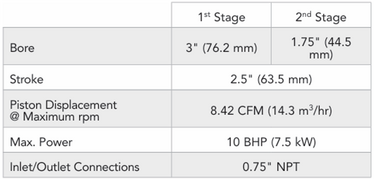

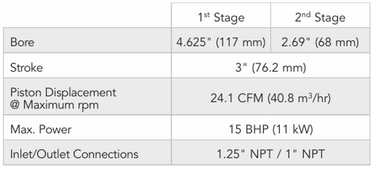

To select an NG Series Compressor that best fits your application requirements, use the charts shown. Actual capacities will depend upon line restrictions, along with the size and length of piping. Horsepower requirements for both liquid-transfer and vapor-recovery applications are based on moderate climatic conditions.

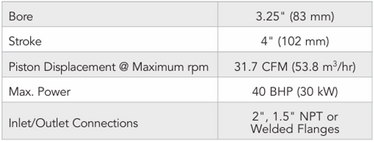

The BLACKMER NG170 Series two-stage reciprocating gas compressors feature flow rates of 14.3 m³/hr at maximum rpm. The compressors feature a two-cylinder design and are available in an BLACKMER NG172 model for natural gas and the BLACKMER NGS172 model for sour gases of up to 8% dry H2S content.

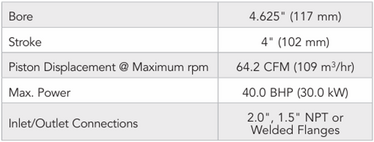

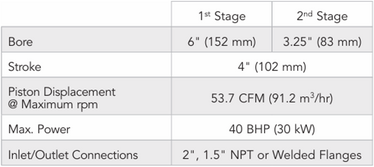

The Blackmer NG610 Series two-stage reciprocating gas compressors offer flow rates of 91.2 m³/hr at maximum rpm. Offering a two-cylinder design, the BLACKMER NG610 Series compressors come in an BLACKMER NG612 model for natural gas and an BLACKMER NGS612 model for sour gases of up to 8% dry H2S content.

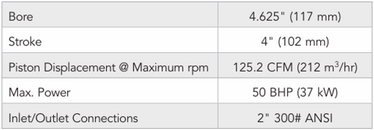

The BLACKMER NG940 Series is the largest Blackmer NG Reciprocating Gas Compressors available with flow rates of 212 m³/hr at maximum rpm. These single-stage, double acting two-cylinder gas compressors are available in two different models, the BLACKMER NG942 for natural gas and the BLACKMER NGS942 for sour gases of up to 8% dry H2S content.

The Blackmer NGH100 Series Reciprocating Gas Compressor is a 100-BHP rated horizontal compressor unit that has been developed for use in vapor-recovery, wellhead-transfer and artificial-lift applications in the upstream oil-and-gas market. It is compatible with sour gas up with up to 8% dry hydrogen sulfide (H2S) content. The BLACKMER NGH100 comes in a two-cylinder, single-stage NGH1013 model, which has a flow rate up to 588 m³/hr at 1,800 rpm, and the BLACKMER NGH1023 model, which is a two-stage, one-cylinder model with flow rate of 172.9 294 m³/hr at 1,800 rpm.