Blackmer-Pumpen für Flüssiggas

Blackmer

BLACKMER LG1 Treibschieber-Pumpen

Die LG1 Gleitschieberpumpen verfügen über 1 Zoll (26 mm) NPT-Anschlüsse mit Gewinde für 180°-Inline-Anschlüsse und können Durchflussraten zwischen 15 und 37 l/min bei Temperaturen von -32 °C bis 115 °C und Arbeitsdrücken von bis zu 24,1 bar erzeugen. Sie bieten zwei Montagearten: Basisfuß (LGB) und Motoradapter für einen NEMA C-Face-Motor (LGF). Die LG1 Gleitschieberpumpen können auch schnell und einfach umgebaut werden.

Erhältlich als Bare-Shaft-Pumpe, Pumpenaggregat oder als komplettes EDS-Skid inkl. Exe/Exd-Motor, Filter, Kugelhähne, Blackmer Bypass-Balve, Manpmeter, Sicherheitsventile ect.

Anwendungen

LPG, Butan & wasserfreies Ammoniak

Zylinderbefüllung mit mehreren Stationen

Flaschenabfüllanlagen

Kleiner Transfer

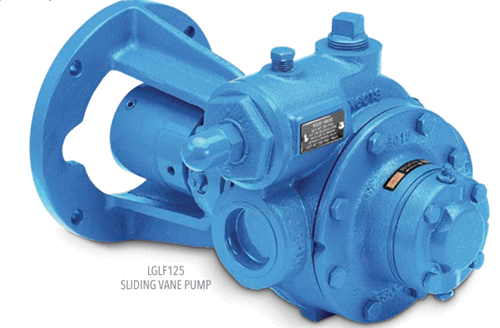

BLACKMER LGL 1.25 & 1.5 Treibschieberpumpen

Die LGL Motor Speed LPG-Pumpen verfügen über 1,25-Zoll- oder 1,5-Zoll-NPT-Anschlüsse mit Gewinde für 180°-Inline-Anschlüsse und können Durchflussraten zwischen 38 und 125 l/min bei Temperaturen von --32 °C bis 115 °C und Arbeitsdrücken bis zu 24,1 bar und einem maximalen Differenzdruck von 10,34 bar erzeugen. Sie bieten zwei Montagearten: Fußmontage an einer gemeinsamen Grundplatte (LGL) und Halterung/Kupplung für die direkte Flanschmontage an einem NEMA C-Face Motor (LGLF). Blackmer® LGL 1.25 & 1.5 Gleitschieberpumpen verfügen über Kavitationsunterdrückungsbuchsen. Diese Technologie mildert Kavitation, indem sie die Kavitation in der Pumpe reduziert. Durch die Reduzierung des Kavitationsgrades werden Vibrationen, Lärm und Verschleiß reduziert.

Erhältlich als Bare-Shaft-Pumpe, Pumpenaggregat oder als komplettes EDS-Skid inkl. Exe/Exd-Motor, Filter, Kugelhähne, Blackmer Bypass-Ventil, Manometer, Sicherheitsventile ect.

Anwendungene:

LPG, Butan & wasserfreies Ammoniak

Zylinderbefüllung mit mehreren Stationen

FlaschenabfüllanlagenKleiner Transfer

Blackmer LGL 2, Blackmer LGL 3 and Blackmer 4 | Treibschieberpumpen BLACKMER LGLD 3 und BLACKMER LGLD 4 Doppelwellenpumpe

LGL-Pumpen werden in den Größen 2, 3 und 4 Zoll angeboten und verfügen über einen 90-Grad-Anschluss, ein internes Überdruckventil und sind in den Modellen mit einseitigen (LGL) und doppelseitigen (LGLD) Pumpenwellen erhältlich. LGL 2-4 Gleitschieberpumpen verfügen über Fördermengen von 114 bis 1.400 l/min und Drehzahlen von bis zu 980 U/min (LGL2, LGL3) und 800 U/min (LGL4). Der maximale interne Druck des Überdruckventils beträgt bei allen Modellen 10,3 bar Differenzdruck. Begleitflansche für NPT- oder stumpfgeschweißte Verbindungen erhältlich. Die Kavitationssuppressionsauskleidung, die nichtmetallischen Duravane und die Endscheiben sind Verschleißkomponenten, die leicht ausgetauscht werden können.

Erhältlich als Bare-Shaft-Pumpe, Pumpenaggregat oder als komplettes EDS-Skid inkl. Exe/Exd-Motor, Filter, Kugelhähne, Blackmer Bypass-Ventil, Manometer, Sicherheitsventile ect.

Blackmer TLGLF Pumpen für Transportfahrzeuge

Die BLACKMER TLGLF Gleitschieberpumpen sind für den Einsatz in Flüssiggas, Butan und wasserfreiem Ammoniak konzipiert. Die TLGLF-Achselpumpen sind in drei verschiedenen Modellen erhältlich - zwei 3-Zoll-Modelle – die TLGLF3, TLGLF3 und TLGLF3HD und ein 4-Zoll-Modell – die TLGLF4. Mit einer maximalen Fördermenge von 1.608 l/min sind die TLGLF4-Pumpen für den Transport, die Be- und Entladung ausgelegt. Der BLACKMER TLGLF3, der für den Einsatz mit Bobtail-Trucks konzipiert ist, verfügt über eine niedrige Leistung von 530 l/min, die sich ideal für kleinere Tankschiffsgrößen eignet. Mit einer um 29 % höheren Durchflussmenge als bei der TLGLF3 erreicht das Modell BLACKMER TLGLF3HD Durchflussmengen von 681 l/min, ideal für Bobtail-Lkw mit hoher Kapazität. Alle BLACKMER TLGLF-Pumpen bieten einen maximalen Differenzdruck von 8,62 bar und können über eine Gelenkwelle oder einen Hydraulikmotor mit einem Adaptersatz angetrieben werden. BLACKMER TLGLF Gleitschieberpumpen bieten Lkw-Betreibern zahlreiche Vorteile, wie z. B.:

Die Gleitschieberpumpentechnologie eignet sich am besten für die Förderung dünnflüssiger Gase wie Flüssiggas

Alle TLGLF-Pumpen können mit Blackmer-Umbausätzen TLGLF3HD TLGLF4 problemlos in einen neuwertigen Zustand umgebaut werden

Selbsteinstellende Schaufeln halten die Durchflussraten auch bei Verschleiß aufrecht

Die Blackmer-Kavitationsunterdrückungsauskleidung mildert die schädlichen Auswirkungen der Kavitation innerhalb der Pumpe

Trockenlauffähigkeit, die das Abisolieren von Leitungen ermöglicht, und hohe Saughubfähigkeiten

Doppelendige Welle für Rechts- oder Linkslauf

Zusätzliche Einlassöffnungen für die Notbe- und -entladung